SiC Substrate Producer 4H 100mm Silicon Carbide Wafer 150dia

HMT supplies 4H-SiC substrates (100/150/200mm) for semiconductor chips. Choose conductive/semi-insulating types & P/R/D grades. Foundation-grade mater...

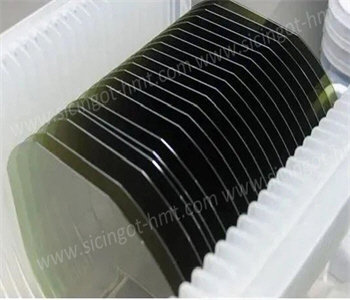

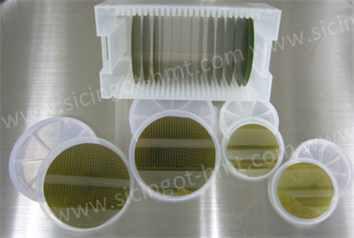

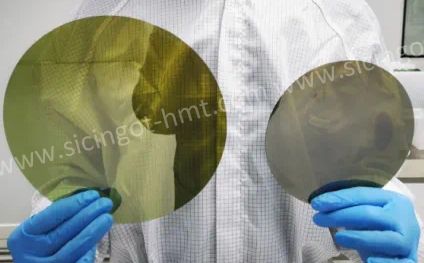

Homray Material Technology (HMT) supplies 4H-SiC substrates in three industry-standard diameters: 100mm, 150mm, and 200mm. Available in both conductive and semi-insulating types, these substrates offer flexible grading options (P-grade, R-grade, or D-grade) tailored to specific project requirements.

When SiC is utilized as the substrate material, production costs are typically higher due to its superior material properties, positioning HMT's solutions as high-value components for advanced semiconductor applications.Silicon carbide (SiC) substrates form the critical foundation of semiconductor chips, analogous to a building's structural base.

Substrate materials have now evolved to the third generation , but the relationship between generations is not one of replacement. Instead, each generation is applied in different fields due to their distinct properties.

First-generation substrates are primarily silicon-based For example, CPUs and GPUs use silicon substrates, and currently, 90% of semiconductor substrates are made of silicon (used in large-scale integrated circuits ).

Second-generation substrates are represented by indium phosphide (InP) and gallium arsenide (GaAs) . Due to their high-speed, high-frequency optoelectronic properties, they are mainly used in optical modules, LEDs, and optoelectronic devices (e.g., **optical communication, optical display, and optical storage ).

Third-generation substrates include silicon carbide (SiC) and gallium nitride (GaN) . Thanks to their high-temperature and high-voltage resistance, they are primarily used in new energy vehicles, photovoltaics, and other fields (for high-frequency, high-power electronic devices ).

Coexistence and Synergy of the Three Generations of Semiconductors

Coexistence and Synergy of the Three Generations of Semiconductors

Complementarity, Not Replacement :

Silicon remains the absolute mainstream for logic chips and consumer electronics (accounting for 95% of the global semiconductor market ).

GaAs and InP dominate high-frequency and optoelectronic niche markets .

SiC/GaN play an irreplaceable role in new energy and industrial applications .

Examples of Technological Integration :

GaN-on-Si: Combining gallium nitride with low-cost silicon substrates for fast charging and RF applications

iC-IGBT hybrid modules : Integrating silicon carbide with IGBTs to improve power grid conversion efficiency .

Future Trends:

Heterogeneous integration: Combining different materials (e.g.,Si + GaN) on a single chip to balance performance and cost.

Ultra-wide bandgap materials: Emerging materials like gallium oxide (Ga₂O₃) and diamond may unlock new applications in ultra-high voltage (beyond 20kV) and quantum computing.

CATEGORIES

LATEST NEWS

- Introduction to the main functions of PbootCMS

SiC : Industrial Ceramic vs Semiconductor Applications

- Introduction to the main functions of PbootCMS

How Does AI Help Singe Crystal SiC Boule Growth

- Introduction to the main functions of PbootCMS

Technical Analysis of SiC Wafer For Power Semiconductor Devices in New Energy Vehicles

- Introduction to the main functions of PbootCMS

SiC industry is stepping into 8 inch with 12 inch substrates making accelerated breakthroughs

CONTACT US

Contact: Mr.Kimrui

Phone: 15366208370

Tel: 15366208370

Email: kim@homray-material.com

Add: LiSheng Industrial Building, 60SuLi Road, WuZhong District, JiangSu Province, P.R.China.