8 inch Conductive 4H-N type SiC Wafer Supplier

Explore HMT's premium 2-8 inch SiC wafers with N-type/SI-type options. Discover semi-insulating & conductive substrates for GaN RF devices in 5G, rada...

SiC Wafers are revolutionizing semiconductor manufacturing with their superior thermal conductivity, high voltage tolerance, and energy efficiency. At HMT, we specialize in producing advanced 2'' (50mm), 4'' (100mm), 6-inch (150mm), and 8-inch (200mm) SiC wafers, driving the industry shift toward large-diameter 12'' SiC substrates for enhanced productivity and cost efficiency.

SiC Wafer Types: Semi-Insulating vs. Conductive

1️⃣ Semi-Insulating SiC Wafers

Resistivity: >1e5 Ω·cm via ultra-high purity crystal growth

Applications:

GaN RF devices for 5G/6G base stations (3-6 GHz bands)

Military-grade radar systems (X-band to Ka-band)

Satellite communication power amplifiers

2️⃣ Conductive SiC Wafers

Doping: Nitrogen-doped for <0.02 Ω·cm resistivity

Applications:

EV power modules (900V+ SiC MOSFETs)

Industrial motor drives

Solar inverter systems

Gallium nitride RF devices prepared with semi-insulated SiC substrate are mainly power amplifiers for communication base stations and radar applications. Gallium nitride RF devices are the most ideal microwave RF devices so far, so it has become the core microwave RF devices in 4G/5G mobile communication systems, a new generation of active phased array radar and other systems.

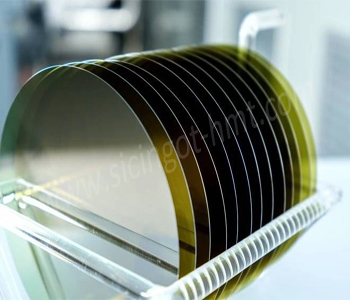

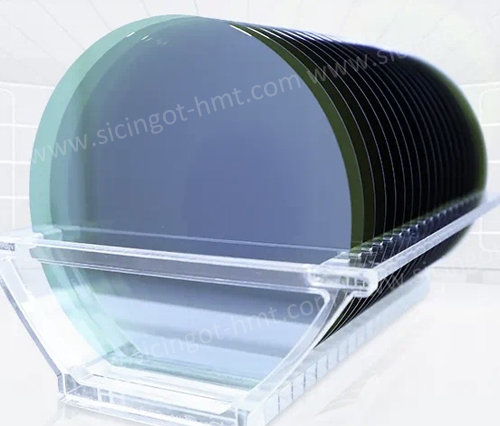

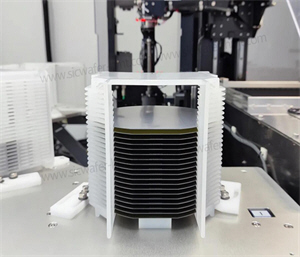

8 inch SiC Substrae wafer and 8 inch SiC Boule Pictures

CATEGORIES

LATEST NEWS

- Introduction to the main functions of PbootCMS

SiC : Industrial Ceramic vs Semiconductor Applications

- Introduction to the main functions of PbootCMS

How Does AI Help Singe Crystal SiC Boule Growth

- Introduction to the main functions of PbootCMS

Technical Analysis of SiC Wafer For Power Semiconductor Devices in New Energy Vehicles

- Introduction to the main functions of PbootCMS

SiC industry is stepping into 8 inch with 12 inch substrates making accelerated breakthroughs

CONTACT US

Contact: Mr.Kimrui

Phone: 15366208370

Tel: 15366208370

Email: kim@homray-material.com

Add: LiSheng Industrial Building, 60SuLi Road, WuZhong District, JiangSu Province, P.R.China.