HPSI 8 inch SiC Wafer Manufacturer AR Glasses

As a leading manufacturer and supplier ofhigh-purity semi-insulating (HPSI) silicon carbide (SiC) wafers, we deliver 4-inch, 6-inch, and industry-lead...

As a leading manufacturer and supplier of high-purity semi-insulating (HPSI) silicon carbide (SiC) wafers, we deliver 4-inch, 6-inch, and industry-leading 8-inch diameters. Our undoped HPSI SiC wafers feature ultra-high resistivity exceeding 1×10⁷ Ω·cm and a standardized thickness of 500±25 μm, ensuring exceptional material uniformity and purity for demanding semiconductor applications.

Three Key Aspects of Introducing High-purity semi-insulating SiC substrates into AR Glasses:

High Refractive Index (2.7) of SiC Substrates:

A single-layer lens made of SiC can achieve a full-color field of view (FOV) exceeding 80°, while resolving the "rainbow artifact" issue commonly seen in AR glasses. In contrast, traditional glass lenses require stacking three layers to reach a 40° FOV. SiC materials enable longer viewing distances, larger FOVs, and clearer visuals. Cost-effective 8-inch SiC manufacturing Specifications for AR Waveguide Lenses:

Cost-effective 8-inch SiC manufacturing Specifications for AR Waveguide Lenses:

Pioneer in large-diameter 8-inch wafer production, driving cost-efficiency for next-gen device scaling.

High-purity semi-insulating SiC substrates are required.

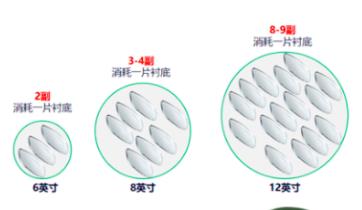

One 6-inch substrate can produce lenses for 2 pairs of glasses.

One 8-inch wafer can yield lenses for 3-4 pairs.

Monochromatic Waveguide Integration:

The high refractive index of SiC allows the combination of three color channels (red, green, and blue) into a single waveguide. Current waveguide designs typically use two or three separate glass layers—each dedicated to one color (or one layer for two colors). Adopting SiC materials reduces the size, weight, and cost of AR glasses.

Enhanced Thermal Management:

SiC’s high thermal conductivity improves heat dissipation in AR glasses. It rapidly transfers heat from optical engines to prevent thermal accumulation, which can degrade optical performance (e.g., rainbow patterns, color shifts). Additionally, wafer-level microstructure design shortens heat transfer paths. By integrating material R&D and optical processing capabilities, low-cost, high-performance AR lenses can be mass-produced.

CATEGORIES

LATEST NEWS

- Introduction to the main functions of PbootCMS

SiC : Industrial Ceramic vs Semiconductor Applications

- Introduction to the main functions of PbootCMS

How Does AI Help Singe Crystal SiC Boule Growth

- Introduction to the main functions of PbootCMS

Technical Analysis of SiC Wafer For Power Semiconductor Devices in New Energy Vehicles

- Introduction to the main functions of PbootCMS

SiC industry is stepping into 8 inch with 12 inch substrates making accelerated breakthroughs

CONTACT US

Contact: Mr.Kimrui

Phone: 15366208370

Tel: 15366208370

Email: kim@homray-material.com

Add: LiSheng Industrial Building, 60SuLi Road, WuZhong District, JiangSu Province, P.R.China.